SAB’s long-standing expertise is key in providing several types of environmental tests.

We carry out vibration tests (acceptance and qualification), drop tests (with a mobile acquisition system), pyroshock tests (with a mobile acquisition system), thermal-vacuum tests (acceptance and qualification), and moment of inertia (MoI) and centre of gravity (CoG) measurements at our facilities.

Sab Test Centre

At the SAB Test Centre, we offer environmental consultancy and testing services.

Vibration Tests

In the SAB headquarters in Benevento, Italy, we perform several vibration tests for the automotive, aeronautical, naval and space industries. Our vibration testing facility offers the following tests:

Sinusoidal

- Resonance Search

- Low-Level Sine Sweep

- Sine Dwell

- Resonance Track

Random

- Classic Random

- Sine on Random

- Random on Random

- Gunfire Test

Shock

- Transient Input (Half Sine, Saw Tooth)

- SRS Input

- Bump Test

Vega Payload Shock Test using VESTA

The VEGA (Vettore Europeo di Generazione Avanzata – European Vector of Advanced Generation) programme dates to the 1990s and was linked to a series of studies exploring the possibility of complementing the Ariane with a small launch vehicle by exploiting its solid booster technology. The ESA approved the programme in the 2000s, with seven countries joining in.

SAB uses the VEGA Shock Test Apparatus (VESTA) to reproduce the dimensioning of the shock load of the VEGA stage separation events (fairing separation) on the spacecraft’s bottom interface.

This service is offered to all payloads flying on VEGA, based on a framework agreement with ARIANESPACE.

As part of VESTA testing, SAB is currently responsible for

- Mechanical integration of the VEGA 4th stage mock-up (A4 Assy)

- Assy instrumentation (accelerometers and strain gauges)

- P/L LPSS937 clamp band integration and tensioning

- HSS (horizontal separation system) belt integration and tensioning

- Handling, checking, installing and firing Pyro bolt cutters (with Pyro operators)

- Acquiring data with a high-frequency DAQ

- Post-processing shock test data

- Refurbishing and servicing electronic and mechanical parts

General Services

We also provide project and test management services and support our customers in AIT and QA tasks.

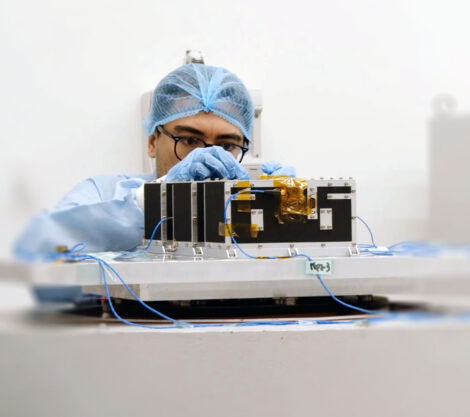

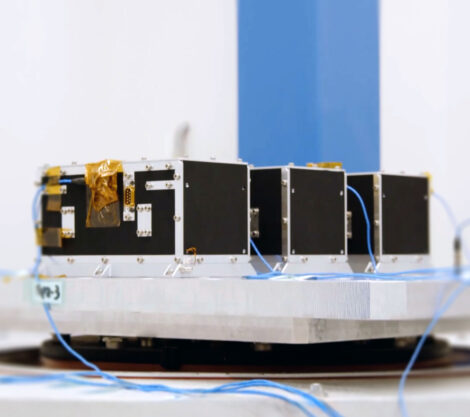

Based on test results, we design and build MGSE. We provide consultancy services on construction/implementation methods and procedures. We also carry out analyses and computational simulations in our ISO 8 class cleanrooms.