As part of its complete satellite design, development, manufacture and integration service, SAB Aerospace uses sophisticated mechanical ground support equipment (MGSE) at the integration stage in an ISO 8 clean room. MGSE for aerospace components is a crucial component in satellite integration and testing. These systems provide the necessary infrastructure and equipment to handle, test and integrate satellites during various phases of their development and mission preparation.

MGSE plays a vital role in ensuring that satellites are properly assembled, tested and ready for launch. Mechanical ground support equipment includes specialised tools and equipment for handling satellites during different stages of their assembly and integration, such as include cranes, lifts and other mechanical devices designed to safely move and position satellites. The integration facility at SAB Aerospace is equipped with the following systems.

Lifting devices

Lifting devices play a pivotal role in safely and precisely handling satellites throughout various stages of integration and testing. These specialised tools, such as overhead cranes and hoists, are designed to lift and position satellites or their components within the integration facility. They are used to manoeuvre satellites to different workstations or testing environments. Equipped with safety features like load monitoring and fail-safe mechanisms, lifting devices ensure the secure transportation and placement of satellites.

Integration trolleys

SAB Aerospace uses integration trolleys as a key component of its MGSE to serve as mobile platforms specifically tailored for assembling and integrating satellite components.

Integration trolleys are designed with adjustable configurations to accommodate different satellite sizes and shapes, providing a versatile and flexible platform for technicians. The mobility of integration trolleys makes it easier to move satellite components within the ISO 8 cleanroom for satellite integration.

The safety features of integration trolleys include fixtures and securing mechanisms that contribute to the efficient and secure integration of various satellite subsystems.

Trolleys

MGSE Trolleys are not restricted to satellite handling but are also used for general purposes, such as transporting tools, equipment, and materials within the facility. Equipped with wheels or casters for easy mobility, trolleys contribute to the smooth handling and transport of assets within the ISO 8 cleanroom and testing areas.

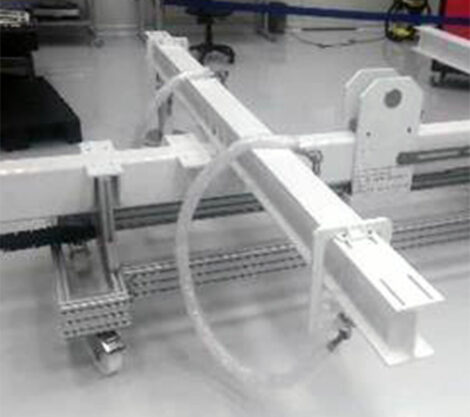

Hoisting devices

SAB Aerospace’s MGSE versatile hoisting devices are engineered to provide vertical and horizontal movement capabilities.

Payloads can be lifted vertically, allowing for precise positioning at various heights and moved horizontally, enabling technicians to transport payloads easily within the integration facility. This flexibility is crucial for efficiently manoeuvring payloads between workstations, testing areas, and transportation containers.

Transport containers

Transport containers are an essential component of a satellite manufacturer’s array of mechanical ground support equipment, designed to move satellites safely and efficiently through the various stages of their development and testing.

Transport containers serve the crucial function of housing and transporting fully assembled or partially integrated satellites within the facility or to external locations.

Customised to the specifications of each satellite, transport containers protect the payload from potential contaminants and mechanical stress during transit. Equipped with securing mechanisms and shock-absorbing materials, transport containers ensure the satellite’s safety by minimising vibrations and impacts during movement.