Responding to the demand for greater efficiency and accuracy in satellite deployment, SAB Aerospace developed the SA4S (SAB Aerospace Small Satellites Separation System).

SAB engineers designed this system to address the complex task of separating the satellite from the launch vehicle at precisely the right moment, imparting the specified velocity to project the satellite into its desired orbit.

Mechanical separation systems tend to use pyrotechnic devices or other mechanical mechanisms to physically disconnect the satellite from the launch vehicle.

Explosive bolts, springs, or other release mechanisms are common components in these systems, but SAB Aerospace’s SA4S is the technological forefront of small satellite deployment.

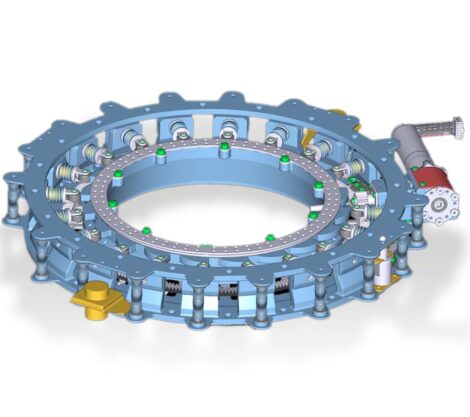

Given the critical nature of satellite deployment, SAB Aerospace’s separation systems are designed to be highly reliable and often incorporate redundancy to mitigate the risk of failure. The SA4S system uses a sophisticated pin-and-release mechanism that connects and subsequently separates two crucial rings, which are the mechanical interfaces with the satellite and the launcher.

The disconnection sequence is initiated by activating 2N redundant EM Motors, propelling the cam ring seamlessly through a precisely calibrated gear set. This ensures controlled and flawless separation, a critical element in delivering the specified velocity to the satellite, ensuring that satellites are deployed accurately and safely into their designated orbits.

Engineering Efficiency for Micro and Minisatellites

Separation systems for satellites play a crucial role in launching and deploying multiple satellites into space.

These systems are designed to safely release one or more satellites from the launch vehicle or from each other in space. The primary goal is to ensure that satellites are deployed with precision and without collisions or interference.

Designed with versatility in mind, the SA4S from SAB Aerospace caters to the diverse payloads of micro and minisatellites. The pin-and-release mechanism accommodates various satellite sizes and configurations, providing secure attachment and guaranteeing structural integrity throughout the launch.

This mechanism, typically involving pins holding the satellite during launch, ensures a straightforward and reliable separation process, contributing to robustness and ease of implementation.

Additionally, pin-and-release mechanisms are cost-effective to manufacture, crucial for small satellites with strict cost constraints. Their lightweight design suits the mass and volume limitations of small satellites. SAB Aerospace rigorously tests pin-and-release mechanisms to ensure their reliability under tough conditions.